- Home

-

Products

- Products and Technologies

- Low-Temperature Catalyst based on Metal Oxides

- Catalyst based on non-Metal Oxides

- Chemical Adsorbents for reducing harmful industrial gases

-

Chemical Adsorbents based

on an Impregnated Activated

Carbon/Metal Oxides - Chemical Adsorbents based on Zeolite

- Healthcare Products

- Semiconductor Traps

- Company

- Contact

- Download

gnb_bg

- HOME

- Products

Low-Temperature Catalyst Total Turn-Key System

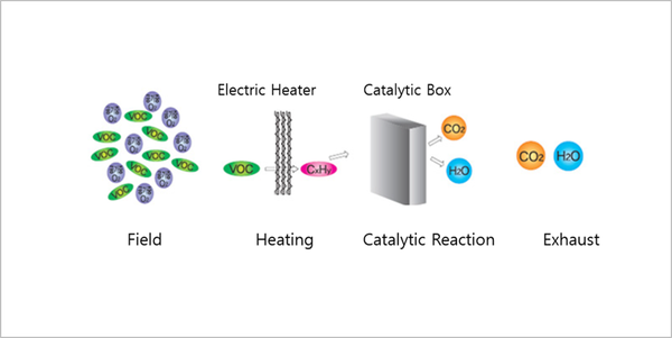

Hanso Inc. has first in Korea developed total turn-key systems using low-temperature catalyst based on metal oxide for converting toxic VOCs(volatile organic compounds) and HCs(hydrocarbons) to non-toxic CO2 and H2O from various places such as plants, manufacturing facilities, offices, etc.

Principle of Application

Total Turn-Key System Advantage

Low cost-of-ownership in operation

- Effective to operate at low-temperature(180-200℃) and good for energy saving thanks to its low-operating temperature compared to the existing technology

- Recovery system of catalytic reaction heat depending on concentrations of VOCs/HCs

- Guarantee 3 years of warranty with no chemical poisoning on catalysts

High efficiency of reducing toxic gases

- Can be operated at 180-200℃ with removal efficiency of VOCs/HCs >98.5% with <2,000ppm of VOCs/HCs

Built-in excellent safety system

- Applicable to various processes and places such as manufacturing factories, plants, offices, etc.

- Compact design with small foot-print makes field tests and installations easy

- Designed to handle a wide range of concentrations of VOCs/HCs during operations

Easy to operate

- Can be operated by electric heating instead of burn type using fossil fuel. HANSO catalysts are good for low-temperature and non-flammable

- Equipped with a detection system of residual gases

- Increased system safety by monitoring controlling system and its parameters in-situ

Environmentally friendly

- Can be used with electricity to elevate system temperature

- No emission of toxic by-products such as NOx from catalytic reactions

- Can be disposed as no-toxic materials after catalytic use due to non-toxic metal oxides

Low-Temperature Catalyst System Configuration

Chamber, Filter, Air Preheating Device, Catalyst Reactor, heat Exchanger, Fan, Emergency Fan, Outlet